Project Location: British Columbia, Canada

Building Type: Two-storey mass timber structure

Structure: Douglas fir – glulam and cross-laminated timber (CLT)

Construction Season: Summer

Building Type: Two-storey mass timber structure

Structure: Douglas fir – glulam and cross-laminated timber (CLT)

Construction Season: Summer

This plan consolidates strategies from RDH Building Science and SIGA best practices for sequencing membranes, ensuring drying potential, and avoiding wetting risks. It emphasizes transitions from below-grade to above-grade and correct installation order to achieve high-performance, resilient enclosures.

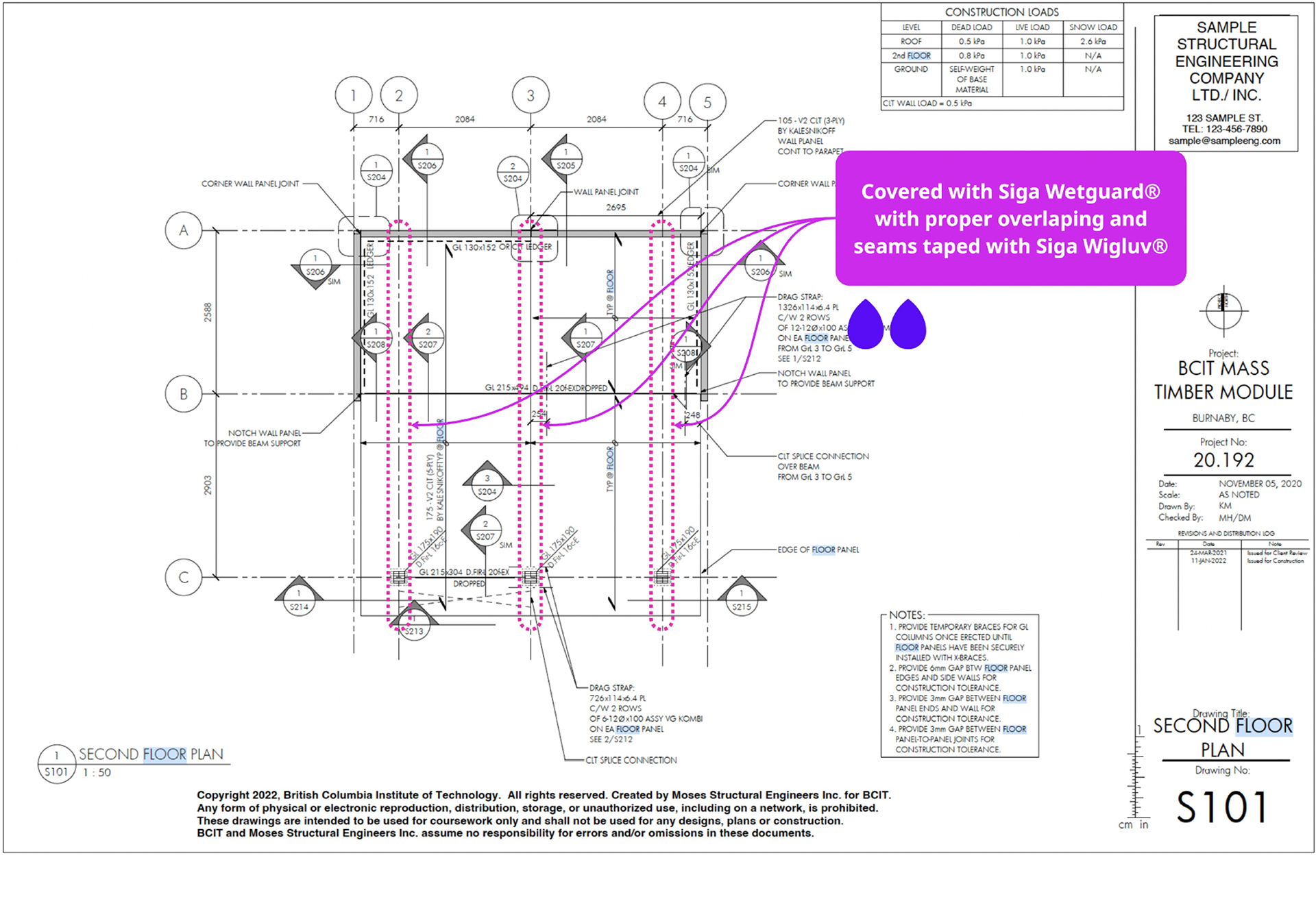

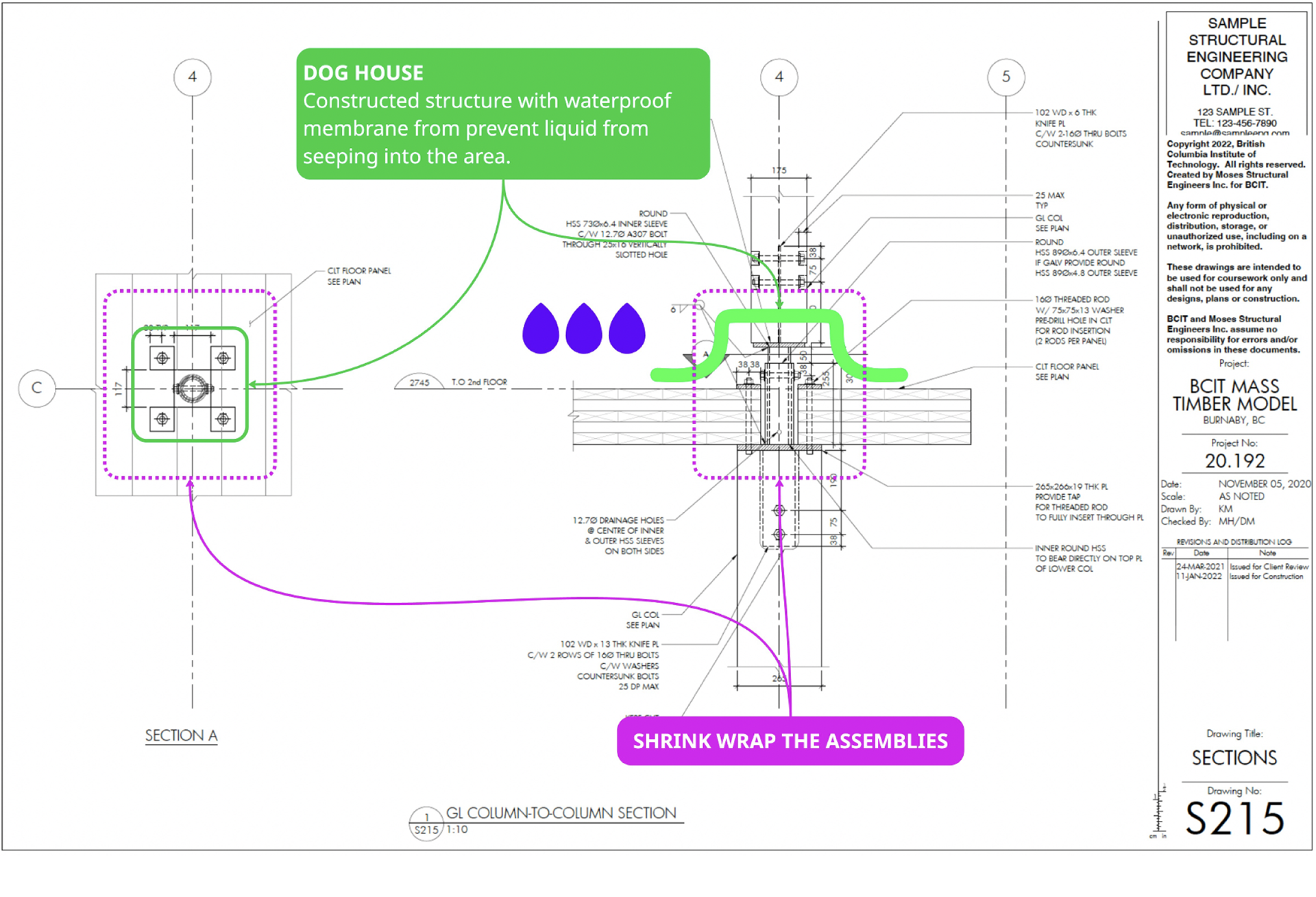

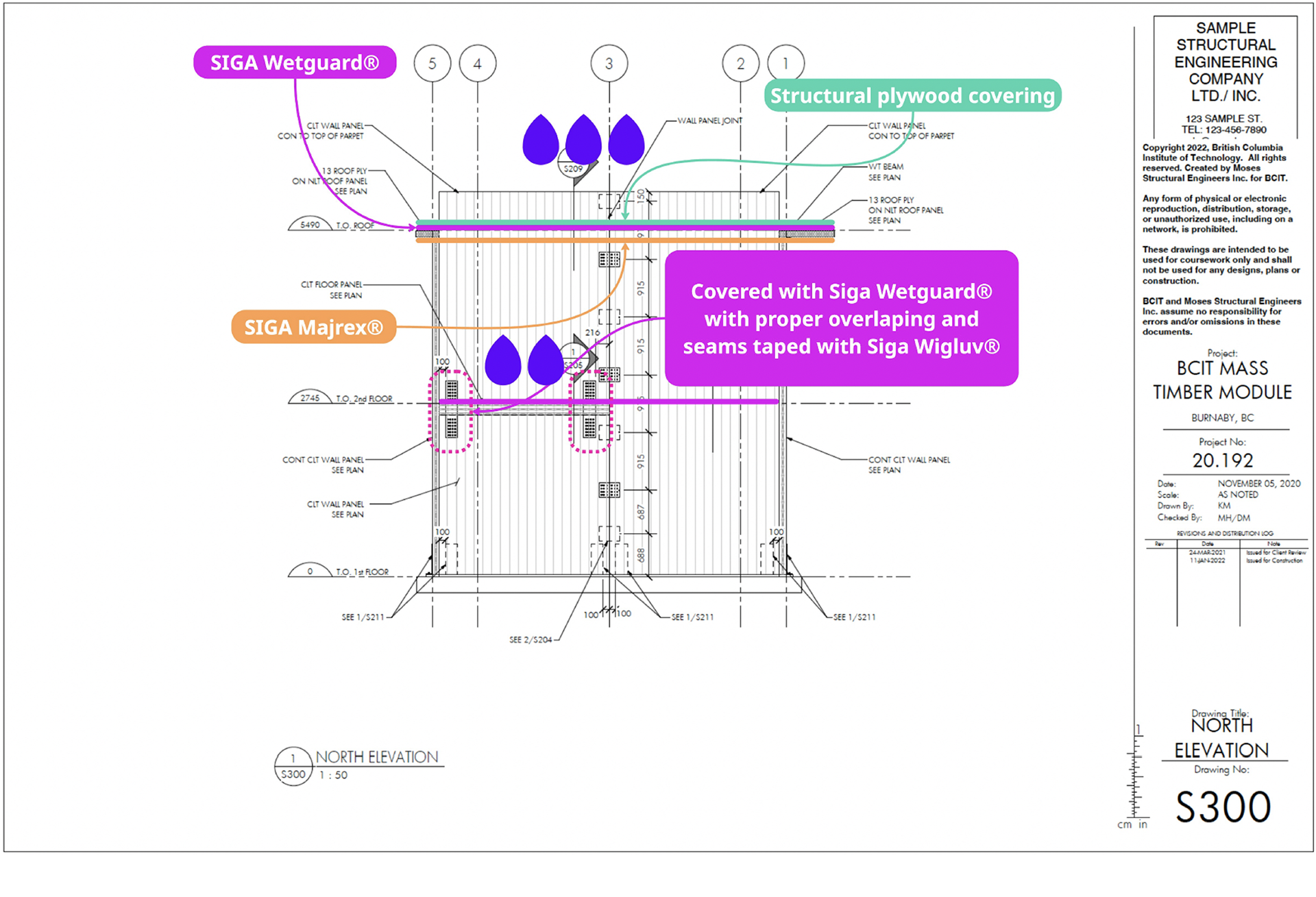

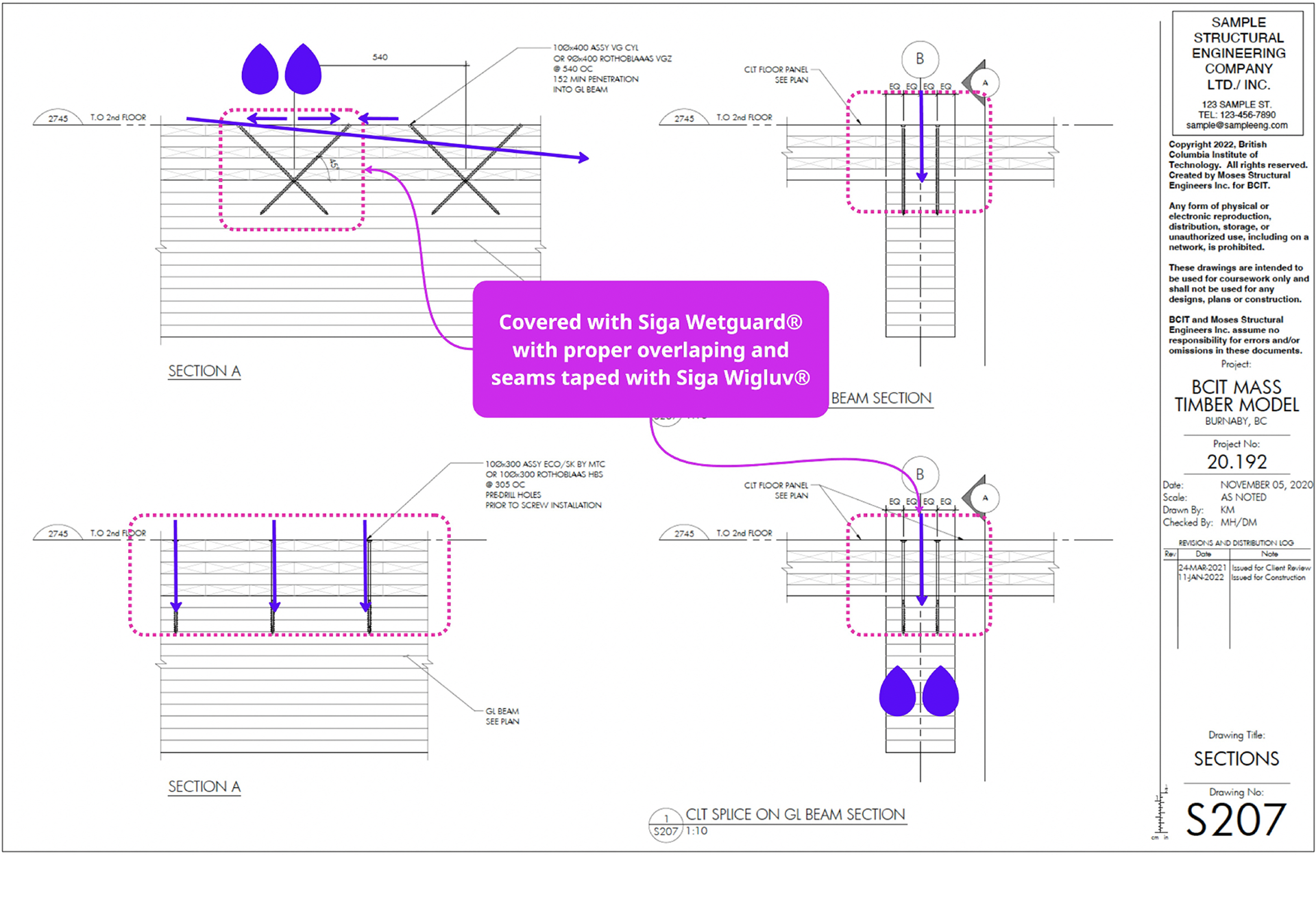

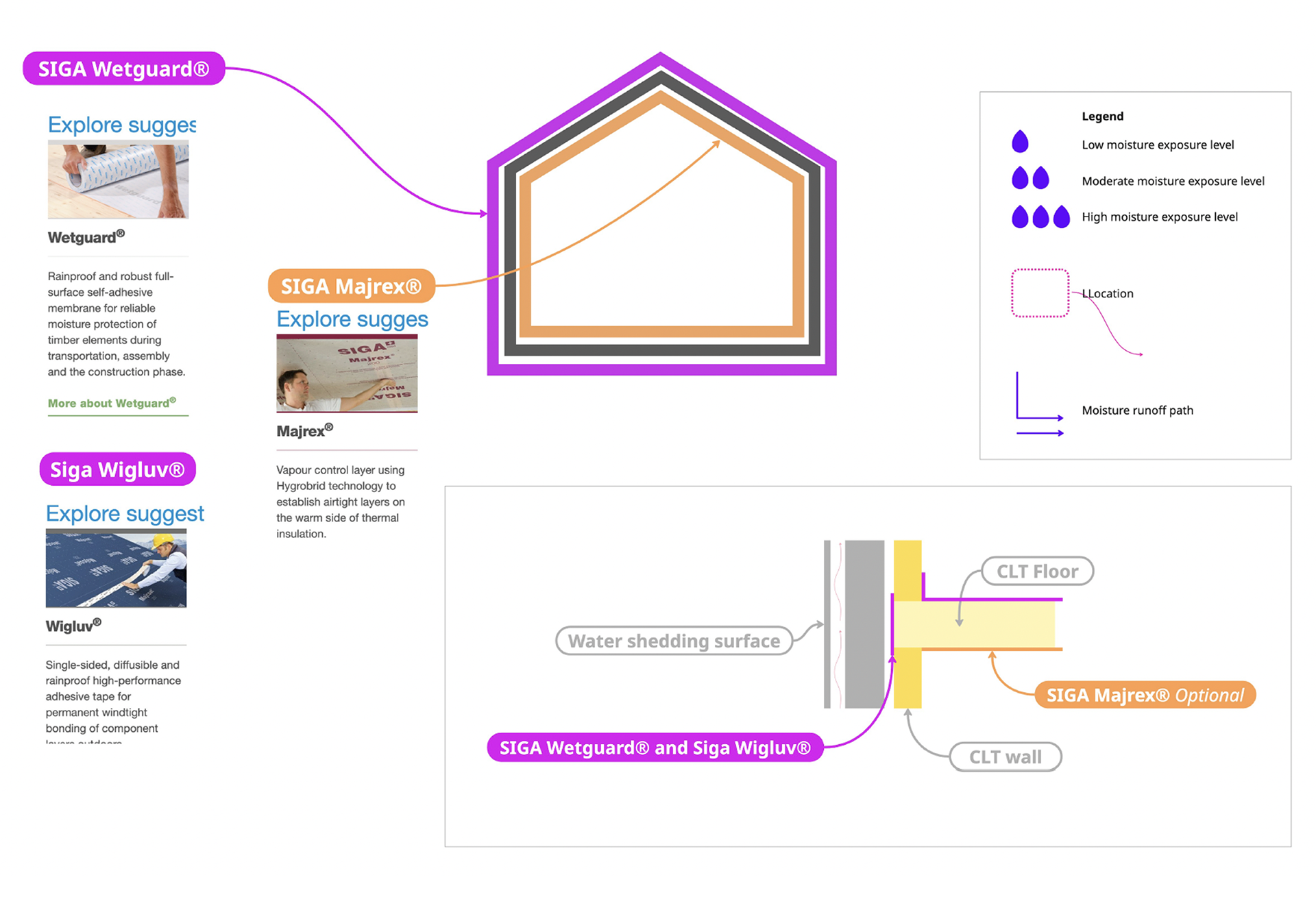

Siga Wetguard® was applied to exposed CLT surfaces before delivery and remained in place through the early erection phases. This temporary weather protection membrane prevented bulk water absorption during transportation and initial site exposure before enclosure was completed.

Siga Wigluv® is a UV-resistant single-sided sealing tape installed on-site to protect cut ends, panel interfaces, and joint terminations. This product was applied at all panel seams, around window rough openings, and at service penetrations to ensure continuity of the water and air control layers.

Siga Majrex® was optionally applied to the underside of CLT ceiling panels as a directional vapour control layer. It was used where interior environmental conditions required enhanced protection against inward vapour drive.

This plan is designed to mitigate moisture risks associated with exposed engineered wood components during the summer construction cycle in British Columbia’s climate zone.

This project has helped me develop technical fluency in sequencing, reading details, and aligning construction practices with sustainable enclosure performance. It also clarified the practical application of high-performance timber assemblies in real-world settings.

Siga Wetguard® was applied to exposed CLT surfaces before delivery and remained in place through the early erection phases. This temporary weather protection membrane prevented bulk water absorption during transportation and initial site exposure before enclosure was completed.

Siga Wigluv® is a UV-resistant single-sided sealing tape installed on-site to protect cut ends, panel interfaces, and joint terminations. This product was applied at all panel seams, around window rough openings, and at service penetrations to ensure continuity of the water and air control layers.

Siga Majrex® was optionally applied to the underside of CLT ceiling panels as a directional vapour control layer. It was used where interior environmental conditions required enhanced protection against inward vapour drive.

This plan is designed to mitigate moisture risks associated with exposed engineered wood components during the summer construction cycle in British Columbia’s climate zone.

This project has helped me develop technical fluency in sequencing, reading details, and aligning construction practices with sustainable enclosure performance. It also clarified the practical application of high-performance timber assemblies in real-world settings.